The RoHS Directive (Restriction of Hazardous Substances) is one of the most important and complex regulations for the electronics industry. Its main goal is to limit the use of certain hazardous substances in electrical and electronic equipment (EEE), presenting a challenge for manufacturers, importers, and distributors who wish to market their products within the European Union. Despite its complexity, this directive helps improve the sustainability and safety of products, making them more environmentally friendly.

What Is the RoHS Directive?

First introduced in 2003 and later updated in 2011 (RoHS 2) and 2015 (RoHS 3), the RoHS Directive seeks to reduce the environmental impact of electronic waste and protect human health by eliminating toxic chemicals.

Restricted Substances Under the RoHS Directive

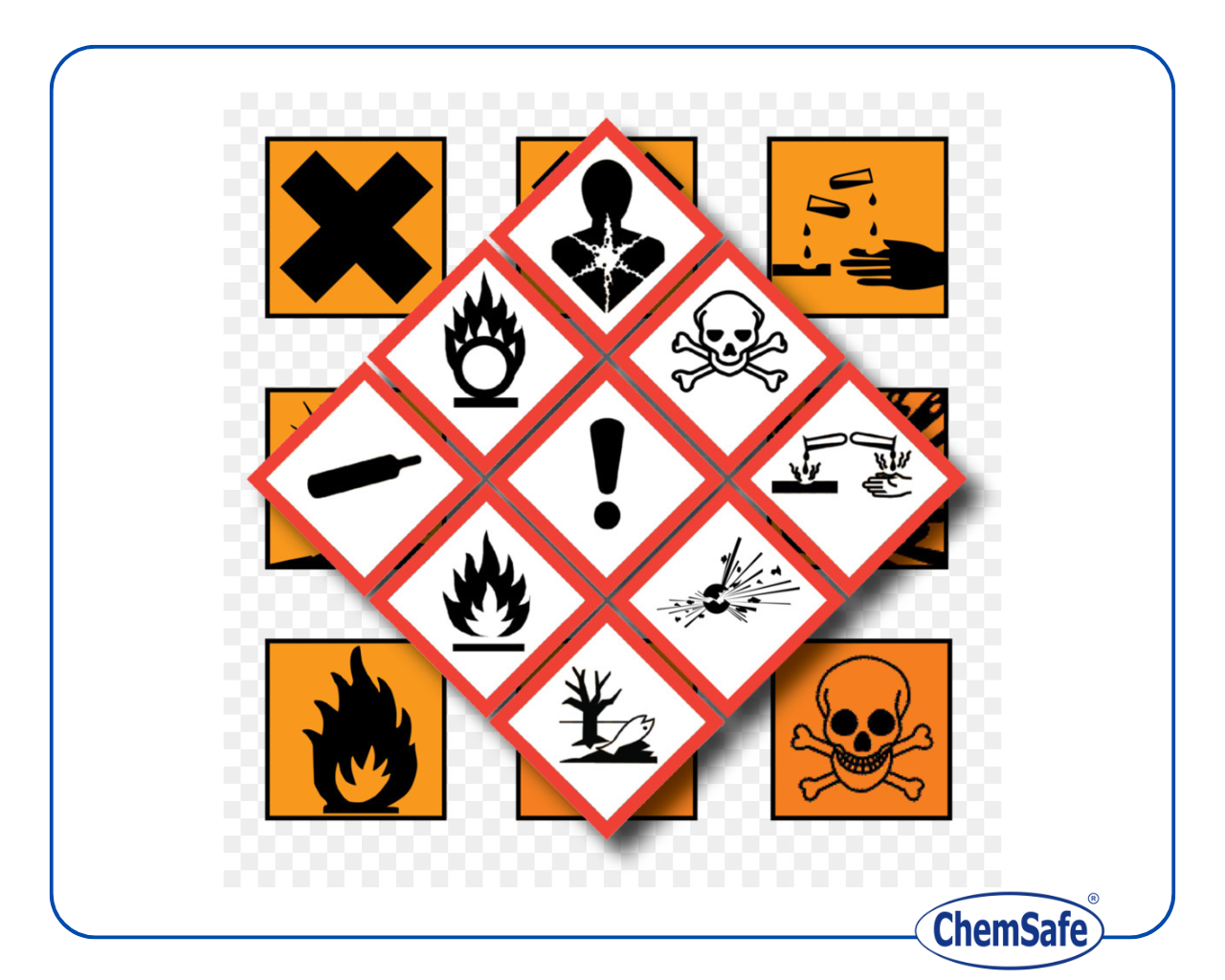

Annex II of this directive lists the restricted substances and their maximum concentration values, which include:

- Lead (Pb)

- Mercury (Hg)

- Cadmium (Cd)

- Hexavalent chromium (Cr6+)

- Flame retardants like polybrominated biphenyls (PBB) and polybrominated diphenyl ethers (PBDE)

- Various phthalates

The maximum allowable concentration of these substances in homogeneous materials is 0.1% by weight, except for cadmium, which is capped at 0.01%. These substances, commonly found in electronic components of small appliances, toys, and leisure or sports equipment, pose risks to the environment and human health if improperly handled.

With RoHS, the EU has imposed strict limits to ensure that devices placed on the market do not exceed allowable concentrations of these substances.

RoHS Compliance Challenges

Compliance with the RoHS Directive is crucial for gaining access to the European market, but it is not a straightforward process. Manufacturers, importers, and distributors have several obligations to meet before placing EEE on the EU market and throughout its life cycle. These include documenting compliance with RoHS requirements, as most restricted substances are not specified by the EEE manufacturer. This requires investigating the supply chain to ensure that the components and materials meet the necessary standards.

Manufacturers must also manage temporary exemptions for certain substances, continuously monitor regulatory changes, and produce detailed technical documentation. Another common challenge is supply chain management, as manufacturers must obtain accurate information from their suppliers about every component used in EEE. Suppliers, in turn, must ensure that their products comply with the hazardous substance restrictions imposed by RoHS.

The RoHS Directive is a dynamic regulation, requiring constant attention to ensure that products remain compliant over time.

Beyond Compliance: Business Opportunities

Conforming to the RoHS Directive is not just a legal obligation but also an opportunity for companies to stand out in a global market, showcasing their commitment to protecting the environment and human health. Moreover, compliance is crucial for avoiding penalties and market restrictions.

For more information, feel free to reach out to us at chemsafe@chemsafe-consulting.com

Sources: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A02011L0065-20240801